Motor

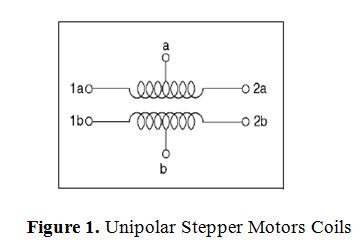

Unipolar stepper motor

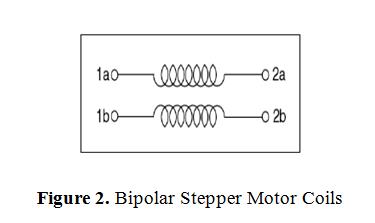

Bipolar Stepper Motor

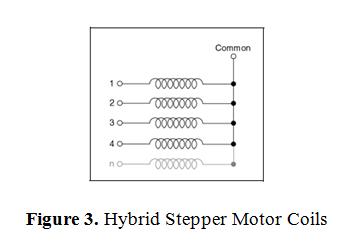

Variable Reluctance stepper motor (hybrid stepper motors)

Driving Unipolar Stepper Motors

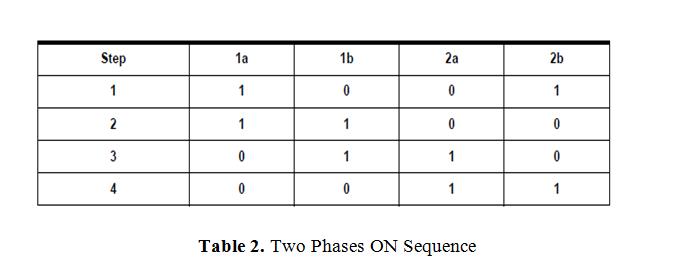

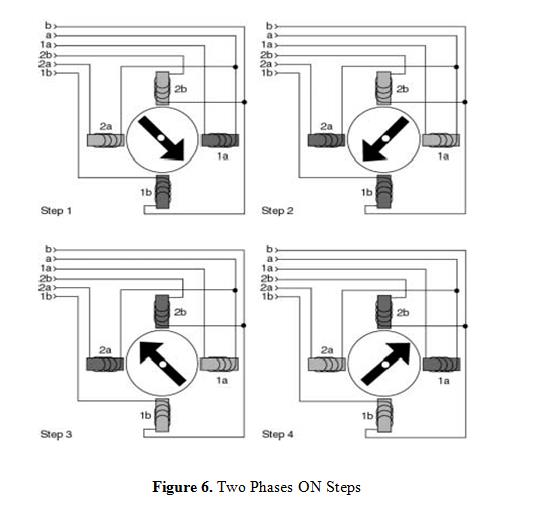

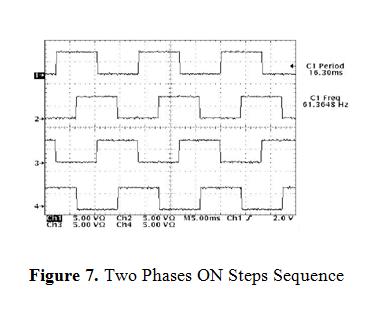

Two Phases ON Mode (Alternate Full step Mode)

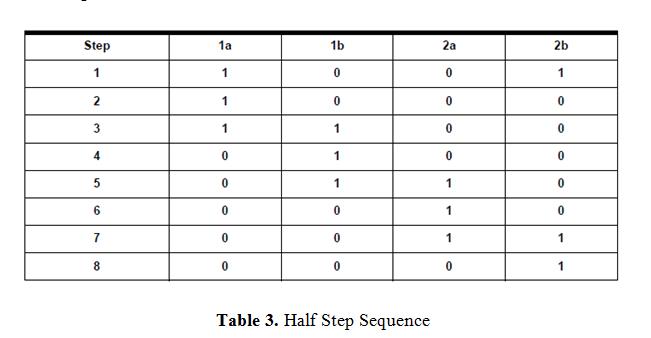

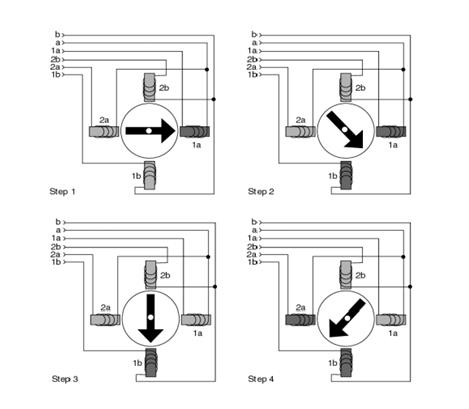

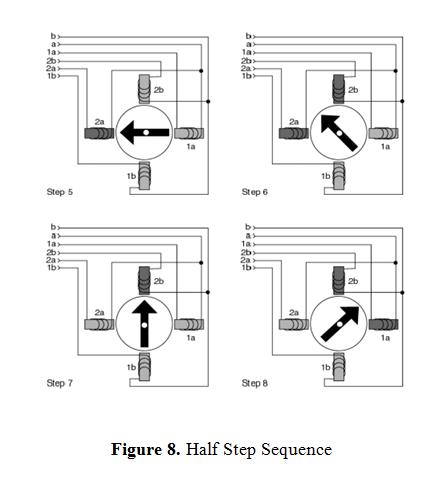

Half Step Mode

Application:

1. They are relevant in consumer office equipment such as printers, plotters, copiers, and scanners.

/* Name : main.c

* Purpose : Source code for interface Stepper Motor with 8051 Microcontroller (AT89C52)

* Author : vijayaraja R

* Date : 2014-01-22

* Website : www.gemicates.org

* Revision : None

*/

/**** Full step drive Mode****/

#include <REGX52.H>

#include<stdio.h>

#define motor P2

void delay(int sec);

void main() //main function

{

do

{

motor = 0x03; //0011

delay(100);

motor = 0x06; //0110

delay(100);

motor = 0x0C; //1100

delay(100);

motor = 0x09; //1001

delay(100);

}

while(1);

}

void delay(int sec) //Function provide msec delay

{

int i,j;

for(i=0;i<sec;i++)

for(j=0;j<1000;j++);

}

/* Name : main.c

* Purpose : Source code for interface Stepper Motor with 8051 Microcontroller (AT89C52)

* Author : vijayaraja R

* Date : 2014-01-22

* Website : www.gemicates.org

* Revision : None

*/

/**** Half Drive Stepping Mode ****/

#include <REGX52.H>

sfr stepper=0xA0; // GPIO P2 declaration

void delay(unsigned int count)

{

int i,j;

for(i=0;i<count;i++)

for(j=0;j<1025;j++);

}

void main() // main function

{

while(1)

{

stepper=0x01;

delay(100);

stepper=0x03;

delay(100);

stepper=0x02;

delay(100);

stepper=0x06;

delay(100);

stepper=0x04;

delay(100);

stepper=0x0C;

delay(100);

stepper=0x08;

delay(100);

stepper=0x09;

delay(100);

}

}

/* Name : main.c

* Purpose : Source code for interface Stepper Motor with 8051 Microcontroller (AT89C52)

* Author : vijayaraja R

* Date : 2014-01-17

* Website : www.gemicates.org

* Revision : None

*/

/**** Wave Drive Stepping Mode****/

/******Single-Coil Excitation******/

#include <REGX52.H>

#include<stdio.h>

#define motor P2

void delay(int sec);

void main() // main function

{

do

{

motor=0x01; // 0001

delay(1000);

motor=0x02; // 0010

delay(1000);

motor=0x04; // 0100

delay(1000);

motor=0x08; // 1000

delay(1000);

}

while(1);

}

void delay(int sec) // Function provide msec delay

{

int i,j;

for(i=0;i<sec;i++)

{

for(j=0;j<100;j++)

{}

}

}

/* Name : main.c

* Purpose : Source code for interface Bipolar Stepper Motor with 8051(AT89C52).

* Author : Gemicates

* Date : 2014-01-22

* Website : www.gemicates.org

* Revision : None

*/

/**** Bipolar Stepper Motor ****/

#include <REGX52.H>

sfr stepper=0xA0; // GPIO P2 declaration

void delay(int);

void main()

{

do

{

stepper=0x01; //0001

delay(1000);

stepper=0x04; //0100

delay(1000);

stepper=0x02; //0010

delay(1000);

stepper=0x08; //1000

delay(1000);

}while(1);

}

void delay(int sec)

{

int i,j;

for(i=0;i<sec;i++)

{

for(j=0;j<100;j++)

{}

}

}